A water cistern plays a foundational role in modern building infrastructure, yet it is often oversimplified or misunderstood during design and specification. In commercial, institutional, and industrial facilities, a properly engineered water cistern is far more than a basic storage cistern. It is a critical system component that supports fire protection, domestic water supply, cooling and HVAC operations, rainwater harvesting, stormwater detention, and emergency supply.

As buildings grow taller, denser, and more technically integrated, the performance of a water cistern directly affects system reliability, regulatory compliance, and long-term operational cost. This is especially true for above-ground water cisterns installed inside basements, vaults, and mechanical rooms, where space constraints, access limitations, and multi-discipline coordination demand a higher level of engineering rigor.

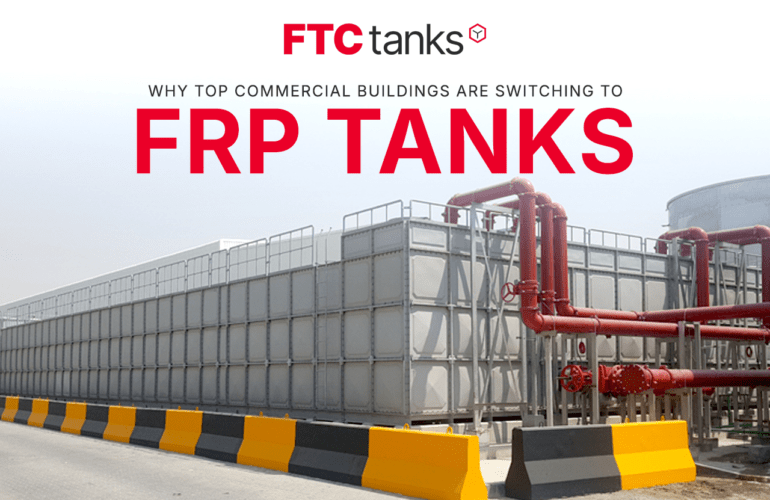

FTC Tanks specializes exclusively in engineered above-ground water cistern systems, providing modular fiberglass panel tanks designed for indoor installation across a wide range of building applications. This article explores water cistern design from a technical perspective, addressing applications, codes, materials, and engineering considerations relevant to engineering design consultants (EDC firms) and end users.

What a Water Cistern Means in Modern Building Design

In contemporary building engineering, a water cistern is best defined as a non-pressurized water storage system designed to supply one or more downstream systems under controlled conditions. Unlike pressure vessels, a water cistern stores water at atmospheric pressure and relies on pumps, gravity, or mechanical systems to deliver the required flow and pressure.

Modern water cisterns are commonly used to support fire protection systems, domestic water storage, cooling and process water, rainwater harvesting, stormwater detention, and emergency backup supply. While the term “water cistern” is sometimes used interchangeably with underground or buried tanks, professional engineering practice increasingly distinguishes between buried tanks and above-ground water cisterns installed within a building envelope or outdoors.

FTC Tanks focuses exclusively on above-ground water cisterns. These systems are installed on structural slabs outdoors, inside basements, vaults, building roofs, or mechanical rooms and are never designed to resist soil or groundwater loads. This distinction is critical, as above-ground water cisterns offer significantly greater accessibility, inspect ability, and long-term reliability compared to buried alternatives.

Above-Ground and Buried Water Cisterns Are Not the Same System

One of the most common sources of confusion in water storage design is the assumption that buried water cisterns and above-ground water cisterns serve the same purpose and can be specified interchangeably. From an engineering standpoint, they are fundamentally different systems with very different performance characteristics.

Buried water cisterns must resist external soil pressure, groundwater uplift, and long-term environmental exposure. These requirements significantly increase structural complexity and introduce inspection and maintenance challenges that often go unaddressed after construction. Leakage in buried water cisterns is difficult to detect, repairs are disruptive, and long-term degradation is common, particularly in aggressive soil conditions.

By contrast, an above-ground water cistern is designed to resist internal hydrostatic loads only and is fully accessible throughout its service life. When installed inside a building, above-ground water cistern allows for routine inspection, straightforward maintenance, and clear code compliance. For this reason, engineering firms increasingly favor above-ground water cisterns for critical building systems where reliability and lifecycle cost matter.

FTC Tanks’ water cisterns are engineered specifically for these above-ground applications and are commonly installed in basements and mechanical spaces where long-term performance can be monitored and maintained.

Typical Locations for Above-Ground Water Cisterns

Above-ground water cisterns supplied by FTC Tanks are designed to integrate into the building structure rather than the surrounding soil. This approach provides flexibility in layout and simplifies coordination across disciplines.

In high-rise and urban buildings, the water cistern is often located in the basement, where it can serve fire protection, domestic water, and HVAC systems efficiently. These basement-installed water cisterns are fully above ground, supported by the building slab, and designed to meet applicable structural and seismic requirements.

Mechanical rooms are another common location for water cistern installation. Locating the water cistern near pumps, heat exchangers, and control equipment reduces piping complexity and improves system performance. Modular panel construction allows FTC Tanks’s water cistern to be assembled inside tight mechanical spaces where monolithic tanks would be impractical.

Vault installations are also common, particularly in facilities where dedicated fire protection or domestic water rooms are provided. In all cases, the water cistern remains accessible, inspectable, and serviceable throughout its lifecycle.

Roof installations are also possible, especially where gravity-fed systems or space constraints drive the design. FTC Tanks’ modular water cistern can be installed on rooftops or upper floors, supported by the building structure and designed to meet applicable load, wind, and seismic requirements. The panelized design allows for on-site assembly, making roof installations practical.

Applications of Above-Ground Water Cisterns in Modern Buildings

While fire protection remains one of the most visible uses of a water cistern, modern buildings increasingly rely on a single water cistern to support multiple systems. Properly engineered, an above-ground water cistern can serve as a flexible and resilient water storage solution across disciplines.

Fire protection water cisterns are governed by NFPA 22 and are used to supply sprinkler and standpipe systems where municipal supply is insufficient or unreliable. An above-ground fire protection water cistern provides clear compliance, straightforward inspection by authorities having jurisdiction, and predictable long-term performance.

Beyond fire protection, many HVAC systems rely on a water cistern to store cooling, process or make-up water. In these applications, a fiberglass panel water cistern offers corrosion resistance and thermal stability, making it well suited for long-term HVAC operation. The ability to locate the water cistern directly in the mechanical room further simplifies system design.

Domestic water cisterns are commonly used in facilities with high demand, intermittent supply, or resilience requirements. Hospitals, laboratories, and institutional buildings frequently specify a domestic water cistern to provide buffering capacity and ensure continuity of service.

Rainwater harvesting systems rely on a water cistern to store collected runoff for reuse. Depending on project requirements, the water cistern may be installed indoors or outdoors, with the design tailored to protect stored water from contamination, freezing, and environmental exposure while supporting proper treatment and reuse.

In some designs, a water cistern is used for controlled stormwater detention, particularly where building-integrated solutions are preferred over site-based systems. Emergency and process water cisterns are also common in mission-critical facilities such as data centers and industrial plants.

Codes and Standards Governing Water Cistern Design

Designing a water cistern requires careful coordination with applicable fire protection, plumbing, mechanical, and structural codes. For fire protection applications, NFPA 22 establishes requirements related to structural integrity, access, drainage, outlet, and seismic considerations. Above-ground water cisterns designed by FTC Tanks are engineered to meet these requirements when used in fire protection systems.

While AWWA standards are primarily associated with municipal water storage, most engineering firms’ reference AWWA principles when designing potable or process water cisterns. In addition, plumbing and mechanical codes govern connections, overflow routing, and backflow prevention associated with water cistern installations.

A water cistern also interacts directly with the building structure. Slab loading, anchorage, and seismic design must be coordinated early to ensure compliance and avoid late-stage conflicts. FTC Tanks regularly works with EDC firms to support this multi-discipline coordination during design and specification.

Material Selection and Long-Term Performance of Water Cisterns

Material selection has a profound impact on the performance and lifecycle cost of a water cistern. Traditional concrete water cisterns are heavy, time-consuming to construct, and susceptible to cracking and leakage over time. Steel water cisterns offer strength but require coatings, painting or lining and ongoing corrosion management, particularly in indoor environments.

Fiberglass panel water cisterns offer a different performance profile. Fiberglass is inherently corrosion resistant, lightweight, and well suited for modular construction. A fiberglass panel water cistern can be transported in components and assembled inside existing buildings, making it ideal for retrofit projects and confined spaces.

FTC Tanks’ fiberglass panel water cisterns are engineered for long service life with minimal maintenance. For engineers and manufacturer representatives, this translates to fewer callbacks, predictable performance, and lower total cost of ownership.

Modular Water Cistern Design for Confined Spaces

One of the defining advantages of an FTC Tanks water cistern is its modular design. Panelized construction allows the water cistern to be assembled in spaces that would otherwise be inaccessible to traditional tank systems. This flexibility is especially valuable in urban buildings, basements, and mechanical rooms with limited access.

Modular water cisterns also allow for future expansion, compartmentalization, and phased installation. In facilities where redundancy or uninterrupted operation is required, multi-compartment water cistern designs provide additional resilience.

Engineering a Water Cistern as Part of an Integrated System

A modern water cistern does not operate in isolation. It must integrate seamlessly with fire pumps, domestic booster systems, HVAC equipment, control panels, and alarm systems. Penetrations, reinforcements, and internal supports must be engineered to accommodate these interfaces without compromising structural integrity.

FTC Tanks designs water cistern systems with these integrations in mind, supporting coordination across plumbing, mechanical, electrical, and structural disciplines. This systems-based approach is particularly valuable for EDC firms managing complex building projects.

Avoiding Common Water Cistern Specification Mistakes

Many water cistern issues originate during specification rather than construction. Treating a water cistern as a commodity, misapplying buried tank assumptions, or overlooking access and maintenance requirements can lead to long-term problems.

Specifying an engineered above-ground water cistern early in the design process helps avoid these issues and ensures that the system performs as intended throughout its service life.

Why Plumbing and HVAC Manufacturer Reps Specify FTC Tanks Water Cisterns

For plumbing and HVAC manufacturer representatives, system reliability and clarity matter. An FTC Tanks water cistern provides a predictable, code-compliant solution that integrates cleanly with pumps, controls, and mechanical equipment. This reduces risk, simplifies coordination, and supports long-term client satisfaction.

The Role of Above-Ground Water Cisterns in Future Building Design

As resilience, efficiency, and lifecycle performance become central to building design, the importance of a properly engineered water cistern will continue to grow. Above-ground, modular, fiberglass water cisterns offer the flexibility and reliability required for modern infrastructure.FTC Tanks remains focused on advancing above-ground water cistern solutions for fire protection, plumbing, HVAC, and multi-use applications in today’s most demanding projects.